Manufacturing Unit

Each and every one of the products is made meticulously at our 12000 Sq. Ft. manufacturing unit in Vasai – Just 30 Km from Mumbai. Our state of the Art manufacturing unit comes with facilities for designing to Mould making to the Final Trial. Our Wide Array of Machines Include:

FOR DESIGNING

- Plastic Product Design & Product Establishment Facility.

- Mould Design Facilities.

- Mould Analysis Software.

- Reverse Engineering Facilities.

FOR MANUFACTURING

- CNC Milling Machines.

- CNC Lathe Machines.

- JIG Boring Machines.

- EDMs – Electric Discharge Machines or Sparking Machines.

- Cylindrical Grinding Machines.

- Surface Grinding Machines, Lathes, Drilling Machines.

- Assembly Table Inspection.

- Mould Validation Facilities - Injection Moulding Machines where Trial and Validation is carried out.

- DESIGN FACILITY

- Mould FLOW SOFTWARE

- MANUFACTURING FACILITY

- ASSEMBLY FACILITY

- QUALITY CONTROL & INSPECTION FACILITY

- Mould VALIDATION FACILITY

DESIGN FACILITY

- Vision Measuring Machines with Reverse Engineering Facilities.

- CMM Machines with the ability to Measure Product and Mould Parts Within 3 Micron.

- Mould Flow Software which Analysis the Mould and gives Precise Corrections.

- Complete CAD/CAM Facilities.

Mould FLOW SOFTWARE

Mould flow software helps us to support first time right concept. One of the keys to a Quality Plastic Injection Moulded Part is an Accurate Mould – One That Produces Consistent Pieces Time and Time Again.

- Mould Flow Plastic Injection Moulding Simulation Software Helps to Optimize The Design of Plastic Parts and Predict Injection Moulding Defects. Access Tools for Injection Mould Design, Plastic Part Design and Mould Processing.

- Access Plastic Simulation Tools for Engineers and Analysts. Optimise Part and Mould Designs to Ensure Moulded Part Quality and Manufacturability.

MANUFACTURING FACILITY

- CNC Milling Machines - 4Nos.

- CNC Lathe Machines – 2 Nos.

- JIG Boring Machines – 1 Nos.

- EDMs – Electric Discharge Machines or Sparking Machines -6 Nos.

- Cylindrical Grinding Machines -2 Nos.

- Surface Grinding Machines -10 Nos.

- Lathes – 5 Nos.

- Drilling Machines – 4Nos.

- Mould Validation Facilities - 3 Nos. ( Injection Molding Machines where Trial and Validation is carried out).

ASSEMBLY FACILITY

Assembly Area is clean with Epoxy Flooring Supported by Power Crane and Other Accessories.

- Assembly Table Inspection -7 Nos.

- Surface Tables -2 Nos.

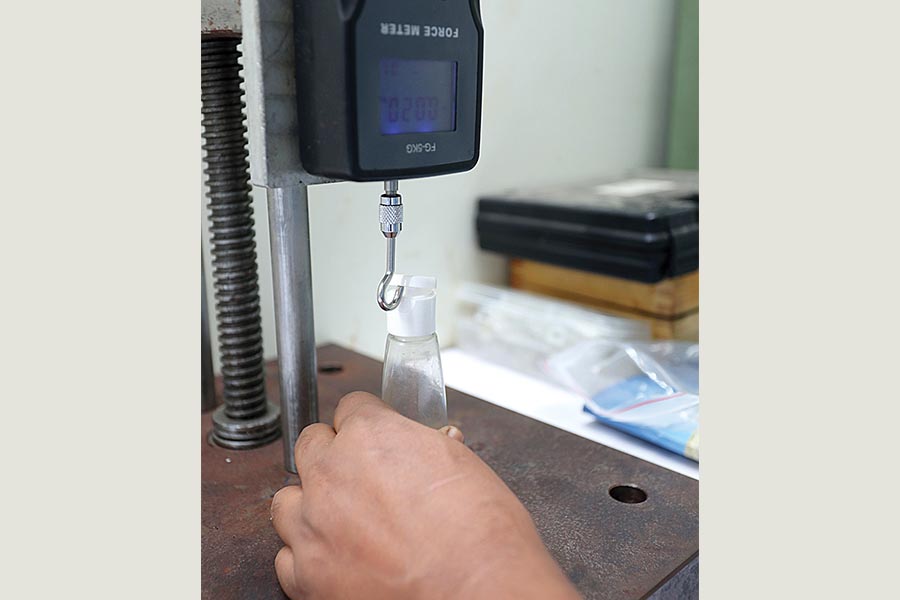

INSPECTION FACILITY

- CMM Machine.

- Vision Measuring Machines.

- Surface Table.

- Height Gauge.

- Angle Plate.

- Vernier Calipers.

- Micro Meter.

- Depth Micrometer.

- Dial Bore Gauge.

- Slip Gauge.

- Pin Gauge.

- Dial Gauge.

- Hardness Tester.

- Comparo Meter.

Mould VALIDATION FACILITY

We take trial Shots & Inspect the Product from all the angles before dispatching the Mould to ensure our customer for Productive & Consistent Mould.

To obtain control on the Processing, we Provides Gauges to Inspect Critical Dimension of Product during & after production that maintain Quality of the Product.

In-house Injection Moulding Machines with Hopper Dryer, Auto Feeder & MTC

1. TOSHIBA: 180 T

2. FERROMATIC: 125 T

3. L & T: 150T

Contact Us Now !

Quality Control

- The commitment towards Accuracy is evident in the Strict Quality Control Measures that we undertake.

- With a Dedication to Perfection, we take responsibility for our actions at every level, which is why our customers have come to expect nothing short of fineness.

- All our QC Engineers are Highly Trained, and make sure no product has faults.

Contact Info

Address

Unit No.3 to 6, Building No. 2, Jai Chamundeshwari Ind. Complex, Naik Pada, Village- Waliv, Vasai (East), palghar-401208, India.Phone

+91 7410040677+ 91 7410040678

marketing@deepplastic.com